Save even more trees and try...

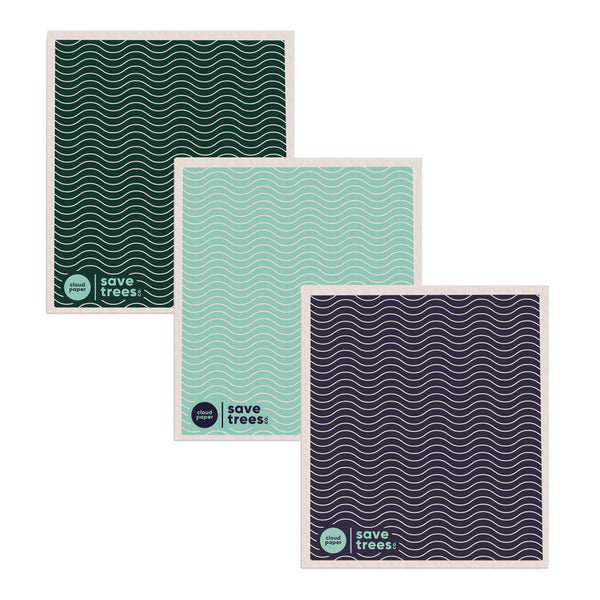

Swish Cloth - Pack of Three

Frequency: Every 4 months

Bamboo Tissues - 12 Boxes

Frequency: Every 6 months

Behind the Scenes of Your Toilet Paper Price Tag

In general, most of us want to be more sustainable. In fact, according to one study 94% of global survey respondents are making some effort to live a more eco-friendly lifestyle.

Some sustainable actions are easy to take, like carrying your reusable water bottle and bringing your own bags to the grocery store. But sometimes, those decisions are a bit more difficult. Especially when it comes to spending your hard earned money. And in many cases, the eco-friendly products that align with your sustainable lifestyle… they end up being more costly than their dollar store counterparts.

There’s no denying this: Bamboo toilet paper tends to be more expensive than traditional tree-based brands.

👉 Why is bamboo toilet paper so expensive?

In short, it has a lot to do with sourcing a more sustainable substance: bamboo.

Today, we’re pulling back the curtain and doing a deep dive into why bamboo toilet paper can be a bit more costly — but (we think) ultimately worth it.

To see the big picture of the costs incurred to create toilet paper you must consider:

To fully understand the cost differences between bamboo and traditional toilet paper, you have to understand a bit about how toilet paper is made. Don’t worry, this isn’t like “seeing how the sausage is made.” The TP process is relatively simple.

Traditional TP starts with chopping down trees which are then shipped to manufacturing facilities where they are processed down into a pulp. Older trees make softer TP, but farming to grow and harvest older trees is costly and time consuming. Instead, most big name brands source their trees from wild old growth forests. Only about 18% of paper products come from farm managed trees. And since shipping tree trunks is also expensive, the toilet paper you buy in the US is usually sourced from the nearby boreal forest of Canada where logging continues to threaten the natural environment.

Depending on the practices of a particular company, the clear-cut forest may be replanted after harvest. If it is, it will still take between 25-100 years to regenerate.

Bamboo TP is very similar in that it starts from cutting bamboo and shipping it to a manufacturing facility to grind it into a pulp. However the bamboo plant is actually a grass, so just like your front lawn when you cut it, it regrows quickly. (Think about how often you have to mow your lawn!) That means it’s a much more sustainable material to farm.

Not all bamboo sourcing is equal, but at Cloud Paper, we source our bamboo from FSC-certified bamboo farms, ensuring that the bamboo is sustainably grown and harvested. (Only about 30% of bamboo toilet paper brands are certified by the Forest Stewardship Council, so be sure to check before you buy).

The species of bamboo used for paper pulp is Phyllostachys Edulis, more commonly called Moso Bamboo. Moso Bamboo takes about four years to regrow for harvest.

This part of the process is pretty much the same for wood or bamboo-based toilet paper with one exception… the bleaching.

After the fiber is pulped, it is bleached. (Psst: bleaching doesn't just make the paper white, it also makes it softer.) Standard corporations seek to make this process as cheap as possible. The cheapest method of bleaching involves toxic chemicals and wastewater.

At Cloud Paper we are committed to using only Elementally Chlorine Free (ECF) bleaching which is the environmentally-friendly method available for bamboo processing at this time. We know that even if it costs a bit more, the benefits are worth it.

After it’s been bleached, the pulp is rolled out into a gigantic sheet and wrapped around what’s called a “parent roll.”

The parent roll is then converted down into its babies — the consumer-sized rolls we are used to seeing. It’s during this part of the process that companies can configure sheet count, number of plies, tightness of the roll wrap, and more.

Once the paper is processed, it must be packaged for the consumer — that’s you!

Again, large corporations take the cheapest route and wrap their toilet paper rolls in plastic. *Sigh*

But at Cloud Paper we aren’t just looking for the cheapest way to create and sell our products. Plastic waste is a major threat to our planet, so we invest a bit more to make sure all our packaging is biodegradable and recyclable. That means you can even throw it straight in your home compost! 🙌

Finally, there’s one last piece to this puzzle: How to connect all the different steps of this process — shipping and transportation!

Another reason why bamboo toilet paper is so expensive is shipping and transportation. Growing bamboo in the United States is quite uncommon. It’s a non-native species, and can be invasive if not managed correctly.

Though we are committed to constantly improving our supply chain, currently the best method for making bamboo toilet paper is to source and manufacture the paper in China where the bamboo can be properly managed, then ship the finished product to the US.

Toilet paper is a lightweight but bulky product. Imagine shipping balloons after they’ve already been filled… it just takes up a lot of space. This adds to the cost, both monetary and environmentally. Understanding this cost, at Cloud Paper we carbon offset 2x the emissions from transportation for every part of the paper’s journey.

Let’s look at a quick breakdown of why bamboo toilet paper is so expensive:

Personally, we think the benefits outweigh the cost. But what do you think? Is the paper worth the price?

P.S. Wondering what is the best bamboo toilet paper to try? We put together this handy comparison chart of six bamboo toilet paper brands to help you evaluate your options.