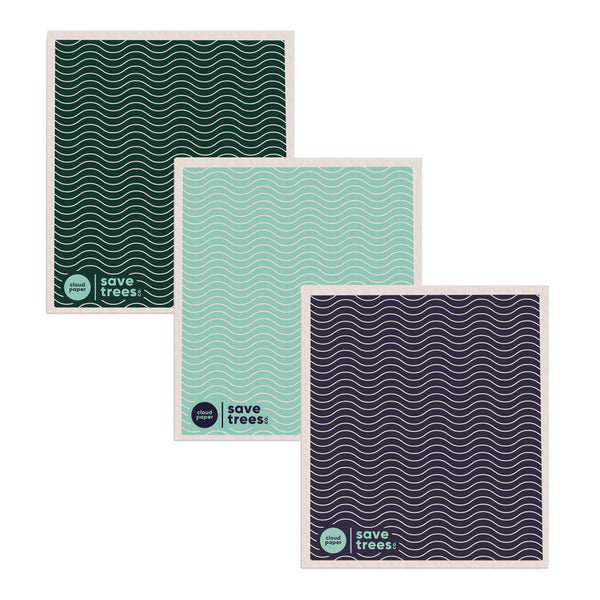

Save even more trees and try...

Swish Cloth - Pack of Three

Frequency: Every 4 months

Bamboo Tissues - 12 Boxes

Frequency: Every 6 months

Toilet paper: we use it not just everyday, but multiple times per day. Yet how often do you think about what actually goes into making your toilet paper?

We’re guessing not a lot. But as with most things, it’s not just the final product and how we use it that impacts the planet – it has a lot to do with the process.

As a company that puts sustainability first, we think it's important to show transparency in all aspects of our manufacturing process. So today we're going to zoom in on one piece in particular: bleaching.

You might be wondering: why bleach toilet paper at all? For printing paper, it makes sense – increasing the contrast makes the text easier to read. An additional benefit is that the bleaching process actually helps the paper last longer.

But… neither of those properties are beneficial to toilet paper. Turns out, the bleaching process does have other beneficial effects for both toilet paper and paper towels.

The bleaching process is what makes toilet paper soft to the touch and increases its absorbency.

Unbleached paper is scratchy and doesn’t do the job of drying quite like bleached paper does. You’ve probably felt the difference yourself from using brown paper towels in a public restroom. Ever try to clean up a spill with those towels? Now think about wiping your… ya… eek! So scratchy!

We prefer the bleached variety, and most of our customers do too. But that doesn’t mean we were willing to trade our own health – or the health of the environment – just for a cushier clean. Advancing technologies have given us options when it comes to the bleaching process, so we have choices. Though there are likely hundreds of different variations, most bleaching methods fall into one of these four categories:

See a trend there? A lot of it has to do with whether or not chlorine is used in the process. Let’s get into why that’s so important.

For nearly a century there was really only one method of paper bleaching: Elemental Chlorine.

Elemental chlorine is a toxin so potent that it was used as a poison gas in WWI. Turns out, it’s also very good at bleaching paper.

This method came under the microscope when environmental researchers discovered a toxic compound called dioxin was coming from the wastewater of nearby paper plants. Dioxins are now known to cause cancer, reproductive problems in both humans and animals, and impair the immune system. Studies have shown they are responsible for deformities in fish and destroy their reproductive cycle.

You might have seen signs by the river warning citizens not to eat the fish, or to limit their consumption per month. These are often the result of high dioxin concentrations.

Dioxins are especially harmful because they have a very long half-life. Half-life, in this case, simply means how long it takes for levels of the toxin to be reduced by half. One dioxin – called TCDD – has been shown to take 7-9 years to drop its toxicity level 50% in the human body.

Because of these stable properties, dioxin has a tendency to accumulate as it moves up the food chain. Think: dioxins are absorbed by a school of minnows, the river bass eat a couple of minnows every day for several weeks, and you eat the bass every Saturday night after a day on the river. This makes it particularly dangerous.

When much of this information came to light in the 1980’s, the EPA finally stepped in and began regulating elemental chlorine bleach. The result is that by the 1990’s almost all paper bleaching in North America switched over to the ECF method: Elemental Chlorine Free.

As the name suggests, the ECF method is free of elemental chlorine (the dioxin producing culprit) and instead uses a compound called chlorine dioxide to achieve bleaching. Though it sounds similar to dioxin, the chlorine dioxide process produces only trace amounts of the toxic pollutant.

ECF bleaching is the most popular method you’ll find in North America, and supporters say that the dioxin produced is negligible.

You might have already deduced, TCF bleaching is totally chlorine free! Instead of elemental chlorine or chlorine dioxide, TCF bleaching uses oxygen based agents or hydrogen peroxide. That means it completely eliminates dioxin pollutants making it safe for the environment and for you.

Then why, you might ask, doesn't everybody use TCF bleaching? Well, while it produces zero dioxins, the system required to perform this method is much more complex (and therefore expensive) than the ECF method. In fact, the required renovations would have been so costly for most paper manufacturers that it was a major factor in EPA regulations continuing to allow ECF bleaching.

There is one other method of bleaching toilet paper. It’s the least common, partially because it only applies to a less common toilet paper material.

PCF is a process used only for bleaching recycled materials. The process itself produces no dioxins, and is considered the most eco-friendly by the Natural Resources Defense Council.

Unfortunately, with the PCF method it’s impossible to know whether the original papers were bleached with elemental chlorine or chlorine dioxide. The concern with recycled paper is that if toxic chemicals were used to produce the original paper, they can get mixed into the recycling process. This is one of the reasons we made the choice to use virgin bamboo fibers rather than recycled paper when we set out to create the most eco-friendly toilet paper.

By far, the most popular bleaching process in North America is ECF bleaching, outnumbering the TCF method 10 to 1. You can probably understand why, with an estimated cost of $1 billion in renovations for the majority of paper plants on the continent to make the switch.

The good news is that since the regulations went into effect in the 90’s, streams and rivers have slowly recovered. Over 90% of the waterways once deemed too toxic for swimming or fish consumption have been cleared for activity again. The fish and amphibian populations have begun to rebound as well, and we couldn’t be happier about that!

At Cloud Paper, we're committed to continuously broadening our impact as a company! We are determined to provide consumers with the most environmentally friendly paper products on the market, and to us that means responsible FSC-certified sourcing, and the ECF bleaching process.

If you’re curious what process your current paper brands use, you can find it listed in the NRDC (Natural Resource Defense Council) Issue with Tissue report, or check out our comparison of the leading bamboo toilet paper brands.